Time:2025-11-26 Views:0 source:CNC Machining customization source:CNC Machining news

A turret punch press is a high-efficiency, automated stamping machine designed to produce large volumes of stamping parts with diverse hole patterns, cutouts, and shapes by leveraging a rotating turret (a cylindrical tool holder) equipped with multiple punches and dies. Unlike single-punch hydraulic or mechanical presses (which require manual die changes for different operations), the turret punch press can switch between up to 60 different tools in seconds—enabling sequential or simultaneous punching, forming, and nibbling operations on metal sheets. This technology is widely used in industries like sheet metal fabrication, HVAC, and electrical enclosure manufacturing, where stamping parts require high flexibility and fast production turnaround.

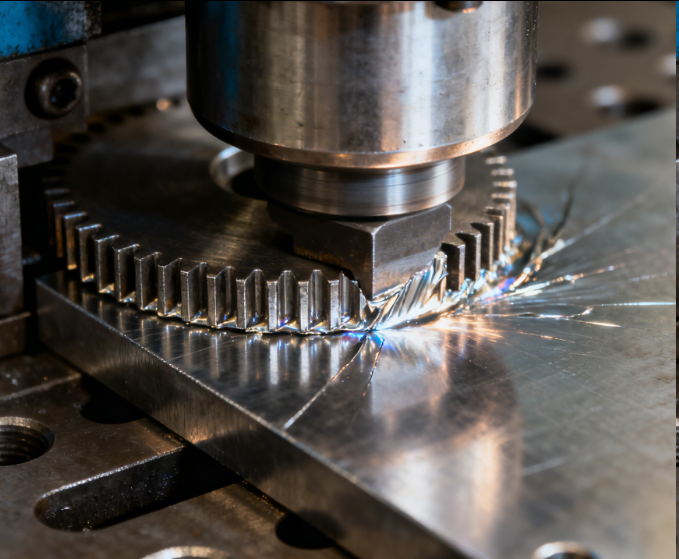

The core working principle of a turret punch press revolves around its dual-turret design (upper and lower turrets) and CNC control system. The upper turret holds a variety of punches (each with a unique shape, e.g., circular, square, rectangular), while the lower turret contains matching dies. A metal sheet (typically 0.5mm to 6mm thick, made of steel, aluminum, or stainless steel) is clamped to a movable worktable, which is controlled by servo motors to position the sheet precisely under the turret. When a punching operation is initiated, the CNC system rotates the turret to align the desired punch-die set with the sheet, then activates a hydraulic or mechanical drive to push the punch through the sheet into the die—creating the desired hole or shape. For complex parts (e.g., electrical panel enclosures with multiple hole sizes), the worktable moves the sheet to different positions under the turret, allowing the press to punch multiple features in a single setup. For example, a CNC turret punch press can produce an aluminum HVAC duct flange with 20 circular holes (8mm diameter) and 4 square cutouts (15mm x 15mm) in 30 seconds, with a positional accuracy of ±0.03mm.

Key advantages of turret punch presses include high flexibility, fast tool change, and multi-functional capability. The rotating turret eliminates the need for manual die changes, reducing setup time by 70 to 90% compared to single-punch presses. For manufacturers producing multiple part types (e.g., 10 different electrical enclosure designs), this means switching between jobs in minutes rather than hours. Additionally, modern turret punch presses integrate forming tools (e.g., embossing, bending, and rolling) into the turret, allowing for both punching and forming operations in one machine—eliminating the need for secondary processing. For example, a press can punch a hole in a steel sheet and then emboss a raised rim around the hole (to strengthen the edge) in the same cycle, reducing production steps and cost.

Equipment components are optimized for precision and durability. The turret is made of high-strength alloy steel with precision-machined tool stations to ensure punch-die alignment (critical for hole quality). The worktable uses linear guides and ball screws (driven by servo motors) to achieve high positional accuracy, even at high feed rates (up to 100 m/min). Advanced models include a “auto-indexing” feature for punches, which allows the turret to rotate the punch (e.g., 45° or 90°) to create angled holes or slots without repositioning the sheet. The CNC system supports CAD/CAM integration, enabling operators to import part designs directly and generate punching programs automatically—reducing programming time by 50% and minimizing human error.

Application-wise, turret punch presses excel at medium-to-high-volume production of sheet metal stamping parts. They are commonly used to produce electrical enclosures (e.g., server racks, control panels), HVAC components (e.g., duct flanges, vent grilles), and automotive sheet metal parts (e.g., bracket mounting holes). For example, a large-scale manufacturer can produce 5,000 steel electrical panel doors per shift using a turret punch press, each with a custom pattern of holes and cutouts, without manual intervention.

Automation and integration capabilities further enhance productivity. Turret punch presses can be connected to automated material handling systems (e.g., coil feeders, robotic arms, and part sorters) to create fully automated production lines. For instance, a coil feeder supplies raw metal sheets to the press, the press punches/forms the parts, and a robot sorts finished parts into bins—allowing 24/7 operation with minimal labor. Advanced models also include real-time monitoring systems (via sensors) to track tool wear, sheet thickness, and punching force—alerting operators to replace worn tools or adjust parameters before defects occur.

Safety and maintenance features are prioritized. The press includes safety guards (e.g., light curtains, interlocked doors) to prevent operator contact with moving parts, and the turret is enclosed to contain scrap material. The CNC system includes self-diagnostic functions to detect issues like misaligned tools or hydraulic leaks, reducing unplanned downtime. Routine maintenance (e.g., lubrication of the turret and worktable) is simplified via accessible service points and automated lubrication systems.

For manufacturers requiring flexible, high-volume stamping of sheet metal parts with diverse features, a turret punch press is a transformative investment. Its combination of fast tool change, multi-functional capability, and CNC precision ensures efficient production of complex parts—meeting the dynamic demands of modern sheet metal fabrication.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts