Time:2025-11-14 Views:0 source:CNC Machining customization source:CNC Machining news

Sheet Metal Processing Pricing is a variable and project-specific cost determined by a combination of technical, material, and production-related factors, making it essential for clients to understand key cost drivers to budget effectively and optimize their designs for affordability. Unlike standardized manufacturing, where costs are fixed per unit, sheet metal pricing adapts to each project’s unique requirements, from material selection to part complexity and production volume.

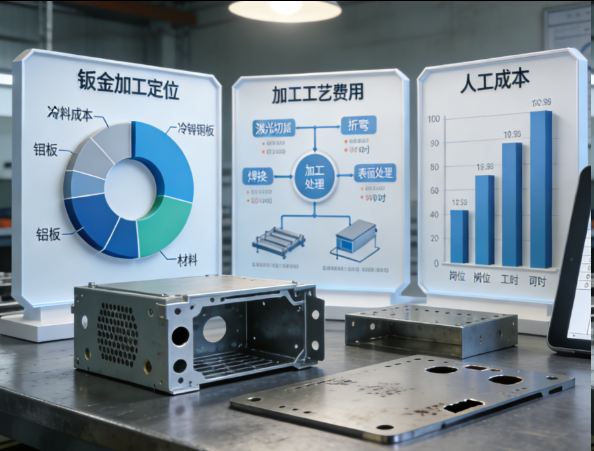

Material cost is the foundational component of sheet metal processing pricing. The type of metal (e.g., aluminum, steel, stainless steel, brass) directly impacts costs: aluminum (6061, 5052) is relatively affordable at (2–)5 per pound, making it ideal for cost-sensitive applications like consumer electronics enclosures. Stainless steel (304, 316L) costs (4–)10 per pound due to its corrosion resistance and strength, suitable for medical devices or food processing equipment. High-performance metals like titanium or Inconel can exceed $30 per pound, reserved for aerospace or extreme-environment parts. Material thickness also matters—thicker sheets (5–25mm) require more raw material and higher processing power, increasing costs by 20–50% compared to thin sheets (0.1–2mm).

Part complexity and processing time significantly influence pricing. Simple parts (e.g., a flat aluminum bracket with 2–3 holes) may cost (5–)20 per unit for low volumes (10–100 units), as they require minimal cutting and no forming. Complex parts (e.g., a multi-bend stainless steel chassis with intricate cutouts) can cost (50–)200 per unit, due to the need for CNC laser cutting (for complex shapes), multiple press brake bends (each adding (2–)5 in labor), and post-processing (e.g., welding, powder coating). Processing technology also affects costs: laser cutting is more expensive than CNC punching for high-volume standardized parts (adding (0.5–)2 per part), but cheaper for complex, low-volume designs where tooling costs for punching would be prohibitive.

Production volume leverages economies of scale to reduce per-unit costs. Low-volume prototyping (1–10 parts) has higher per-unit costs ((20–)500) due to setup fees (programming, tooling, fixturing) of (100–)500. Medium volumes (100–1,000 parts) reduce per-unit costs by 30–50% as setup fees are spread across more units. High volumes (1,000+ parts) can lower costs by 60–70%, especially with automated processes like robotic welding or conveyor-based powder coating. Post-processing adds another layer of cost: powder coating costs (2–)8 per square foot, anodizing for aluminum costs (1–)4 per part, and welding adds (5–)20 per joint depending on complexity. For clients, optimizing designs (e.g., reducing bends, using standard materials, increasing volume) is key to controlling sheet metal processing costs without compromising quality.

Read recommendations:

Sealing ring Precision electronic parts

Housing components for recessed downlights Precision electronic parts

Oval Magnetic Hardware Precision electronic parts